Product Description

GCR Pure Color Series is introducing a new clear liquid designed to Intended Uses:

rejuvenate exterior faded colors on a multitude of surfaces to their original and shiny appearance. Product features include:

- UV Stable

- Excellent Adhesion

- Excellent Chemical & Corrosion Resistance

- Protects New Finishes from Harsh Elements

- Instantly Renews Faded, Dull Colors to its Original Form

- Dirt and Water Repellent

- Easy to use, single component

- Cost Effective

Intended Uses:

- Acrylic

- Architectural, Commercial and Industrial

- Automotive: Plastic Trim

- Coated Surfaces

- Fiberglass

- Plastic

- Polished, Raw and Anodized Aluminum

- Vinyl and many more ....

Product Characteristics

Resin Type: Proprietary

Color: Clear slight yellow liquid.

VOC Compliant: ≤150 g/L

Viscosity (Brookfield DV2T Cone and Plate): 19.91 cP

Flammable

Solids by Volume: 42% (± 2)

Density: 0.89 g/mL

Single Component

Drying Schedule Temperature/Humidity Dependent:

Air Cure and Tack Free: 15 to 30 minutes

Fully Cure: 24 Hours

Shelf Life: 12 months, unopened @ 77°F.

Re-inspect after one year.

Storage: Store at 45°F-90°F. Keep from prolonged exposure to sunlight and heat. Keep closed during storage. If product is opened, securely reseal.

Shipping Packaging Information

| Shipping Weight | Packaging |

|---|---|

| 1 gallon = 10 pounds | 4 gallons per case |

| 5 gallon = 36 pounds | 5 gallon pails are not boxed |

This product is classified as Shipping Class 55.

Contact Information

Technical questions or warranty issues, please contact:

GENESIS COATINGS (800) 533-4273

Theoretical Coverage Rate

The following coverage rates are for estimation purposes only. To accurately determine coverage rates, apply a test application on the actual surface. Surface porosity and texture, method of application and climate conditions affect application rates:

Recommended Film Thickness: 0.25 – 0.5 mils Theoretical coverage per gallon @ 1.0 mil DFT: 673 ft2

Limitations

Do not apply product in rain, high humidity or wind. The information provided is to be used as a guideline only. Specific jobs may require additional information. Please contact your Sales Representative or GCR Representative at (800) 533-4273 for further information. The GCR Pure Color Series is highly sensitive to solvents containing hydrocarbons. When cleaning the surface, use only industrial detergents and rinse thoroughly with water.

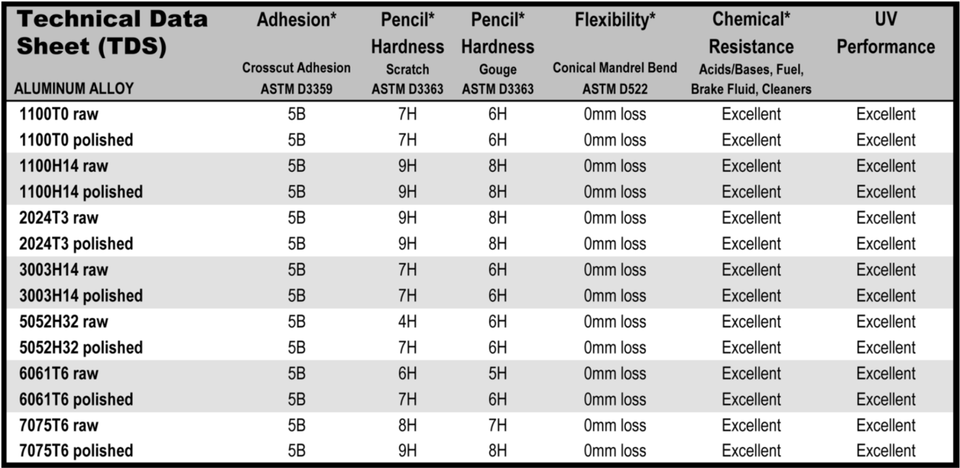

All data is based on the following conditions: Coating applied at 0.25 - 0.5 mil thickness and air cured for 24 hours prior to testing.

* Testing parameters are as follows:

- Adhesion is measured on a scale of 0B, 1B, 2B, 3B, 4B, 5B, with 5B being the highest achievable rating.

- Hardness or Pencil Hardness Tests are measured from softest to hardest as follows: 9B, 8B, 7B, 6B, 5B, 4B, 3B, 2B, B, HB, F, 2H, 3H, 4H, 5H, 6H, 7H, 8H, 9H. 9H is the hardest.

- Flexibility or Conical Mandrel Bend: “0mm loss” is the highest achievable rating and indicates that the coating did not crack or spall.

- Chemical Resistance: Contact us to discuss your specific chemical requirements.

Preparation

Qualifications: Skilled contractors, who are trained, experienced, and familiar with acrylic systems should use product. Contractor must thoroughly read tech spec, label, and SDS prior to application. If there are any additional technical questions, call either the Distributor or the Manufacturer before commencing the job.

Preparatory Work: Surfaces must be clean, dry, and in sound condition. Remove all oil, grease, dirt, loose rust, and other foreign contaminants to ensure proper adhesion. Cleanliness standards are strongly suggested.

Primer: Not required. Apply directly to surface.

Aluminum/Metal: Metal that has been exposed to the environments, must be free of all oils and grease by cleaning with a mild detergent and hot water. High polished aluminum is very easily scratched, so it should be washed very carefully by hand with a non-abrasive micro fiber type cloth. Surface should be dried with clean compressed air, making sure not to leave any water spots behind. Non-painted metal that has been exposed to the environment should be scrubbed with a steel wool to remove any mineralization build-up. Remove any residue with acetone.

Previously Painted Surfaces: If in sound condition, thoroughly clean surfaces of all foreign material. Test material prior to application. Do not apply to weathered peeling, or damaged coatings.

Plastic, Vinyl, Leather and Stone: Surfaces should be cleaned thoroughly with soap and water or a mild degreaser. Hard to reach areas should be scrubbed with a brush making sure to treat with care to avoid any damage. Apply degreaser to any previously treated surface with wax, conditioner or silicon-based products.

Application Equipment

Pure Color Series Liquid is sprayable, but for hard to reach or small surfaces, it can also be applied by hand.

The following is a guide. Changes in pressures and tip sizes may be needed for proper spray characteristics. Always purge spray equipment with acetone.

Reducer: Ready to use. Do not reduce.

HVLP (i.e. IWATA LPH-80): Pressure: 30 PSI

Filter: 325 mesh

Tip: 0.8 mm

NOTE: Applicator must use precaution when spraying coating. Avoid overspraying and spillage. Utilize proper OSHA safety standards when applying in confined areas. Above equipment is to be used as suggestions. Other equipment may be substituted. Pure Color Series Liquid can be applied by hand using a microfiber cloth or sponge.

Application

Shake product before use.

Application Conditions:

Temperature: (air, surface, material): 50°F/10°C minimum – 95°F/35°C maximum

Relative Humidity: 85% maximum

NOTE: Temperature, humidity and direct exposure to sunlight directly affect dry time. It is recommended to apply in a shaded area, away from sun exposure.

Ready for application with HVLP spray gun and will typically only require a single coat for most surfaces.

Aluminum: For best results apply GCR Pure Color Series Liquid immediately after surface preparation. Apply a single coat at a 0.25 to 0.5 mil dry film thickness. Best results will be achieved if using a mil gauge and working from the most difficult to easiest area. Allow parts to air dry between 15-30 minutes and avoid touching as coating is still wet.

For applications by hand: Use nitrile gloves at all times. Wet a microfiber cloth and apply to the surface ensuring to create an overlap with each pass. A second coat may be applied to plastic or vinyl surfaces, before the first coat cures.

Performance Tips

For any defects during application, clean right away with acetone and reapply coating again.

Test product on substrate prior to application to insure adhesion, desired color and finish, compatibility, and performance.

During the early stages of drying, the coating is sensitive to rain, dew, and moisture

NOTE: Certain applications will require technical assistance. Manufacturer will determine specifications on a per job basis. Please contact your Sales Representative or GCR Representative at for technical or warranty issues: GENESIS COATINGS INTERNATIONAL INC

2780 La Mirada Drive Suite D Vista, Ca 92081

(800) 533-4273 info@genesiscoatings.com

Performance Tips

Important: Proper methods to protect over spraying should be implemented. Atomized particles will adhere to most surfaces and are extremely difficult to remove. Do not allow material to dry onto surface, skin or hair.

Precautions: Please read Safety Data Sheets (SDS) carefully. Use only with adequate ventilation. Prevent breathing of spray mists. In confined areas, wear a properly fitted respirator during application until all vapor and spray mists are gone. Protect eyes and skin. Do not take internally. Do not use if you have had a prior reaction to acrylic resins.

KEEP OUT OF REACH OF CHILDREN!

Limited Warranty:

The liability of the Manufacturer and/or Distributor to the Buyer or a third party, for any lost or damages, whether direct or otherwise arising out of the purchase of product from Seller by Buyer shall not exceed the total amount billed and billable to the Buyer of the Product hereunder. In no event will Manufacturer and Seller be liable for any loss of profits or other special consequential damages, even if Seller has been advised of the possibility of such damages. The foregoing limitation on liabilities is in lieu of all other warranties expressed or implied including, but not limited to, those concerning merchantability and fitness for a particular purpose

CONTACT

(760)599-6011

(800)533-4273info@genesiscoatings.com

International Contacts

© 2020 All Rights Reserved | Genesis Coatings | Website Design by GoBeRewarded